De.OXO Biogas®

Ultra-pure before upgrading

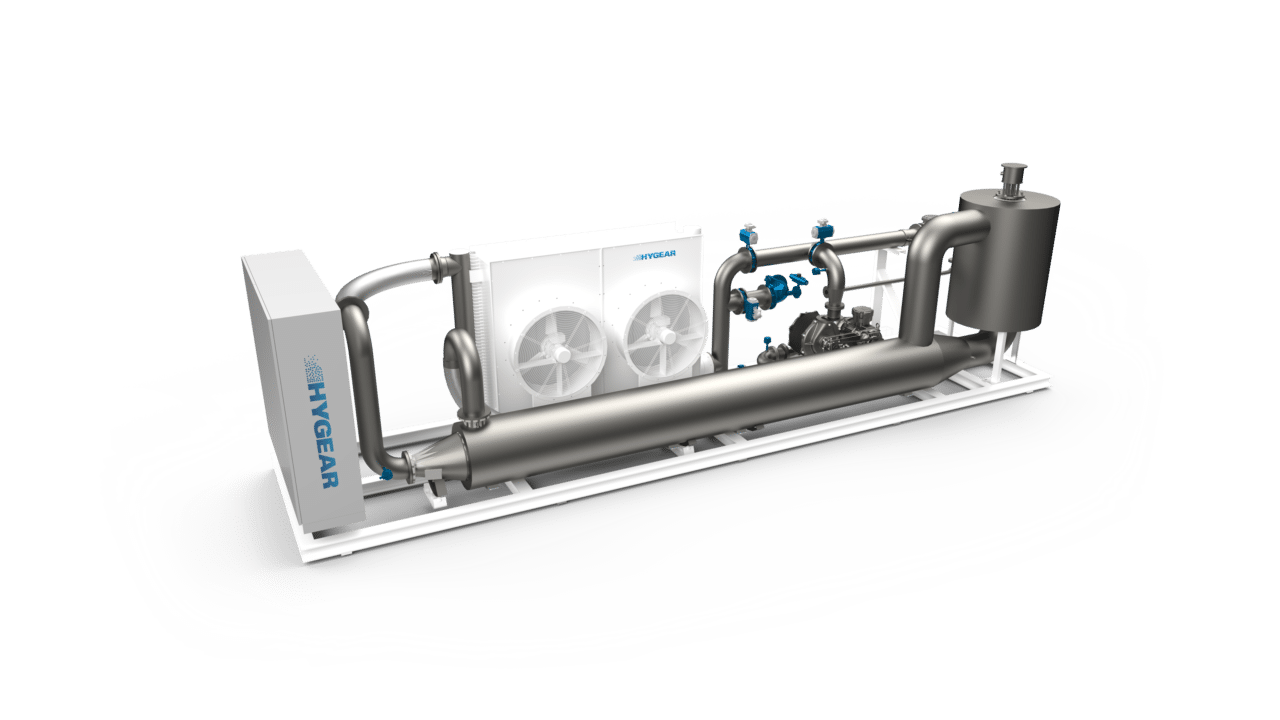

HyGear’s compact De.OXO Biogas® system for biogas deoxygenation removes oxygen from biogas before the upgrading process. It easily integrates with any biogas upgrader to increase biogas purity to oxygen levels as low as <5 ppmv. Additionally, it increases the overall value of biogas. Removing oxygen and impurities before upgrading is essential to comply with strict regulations for injecting biomethane (RNG) into the gas grid.

Features De.OXO Biogas®

- Removes oxygen from biogas.

- Purifies biogas stream before biogas upgrading.

- Improves operational efficiency.

- Operations at low pressure (almost at atmospheric pressure).

- Easy-to-integrate with any biogas upgrader.

- Completely skid built and easy transport in a container.

- Cost reduction*.

Smart design & easy integration

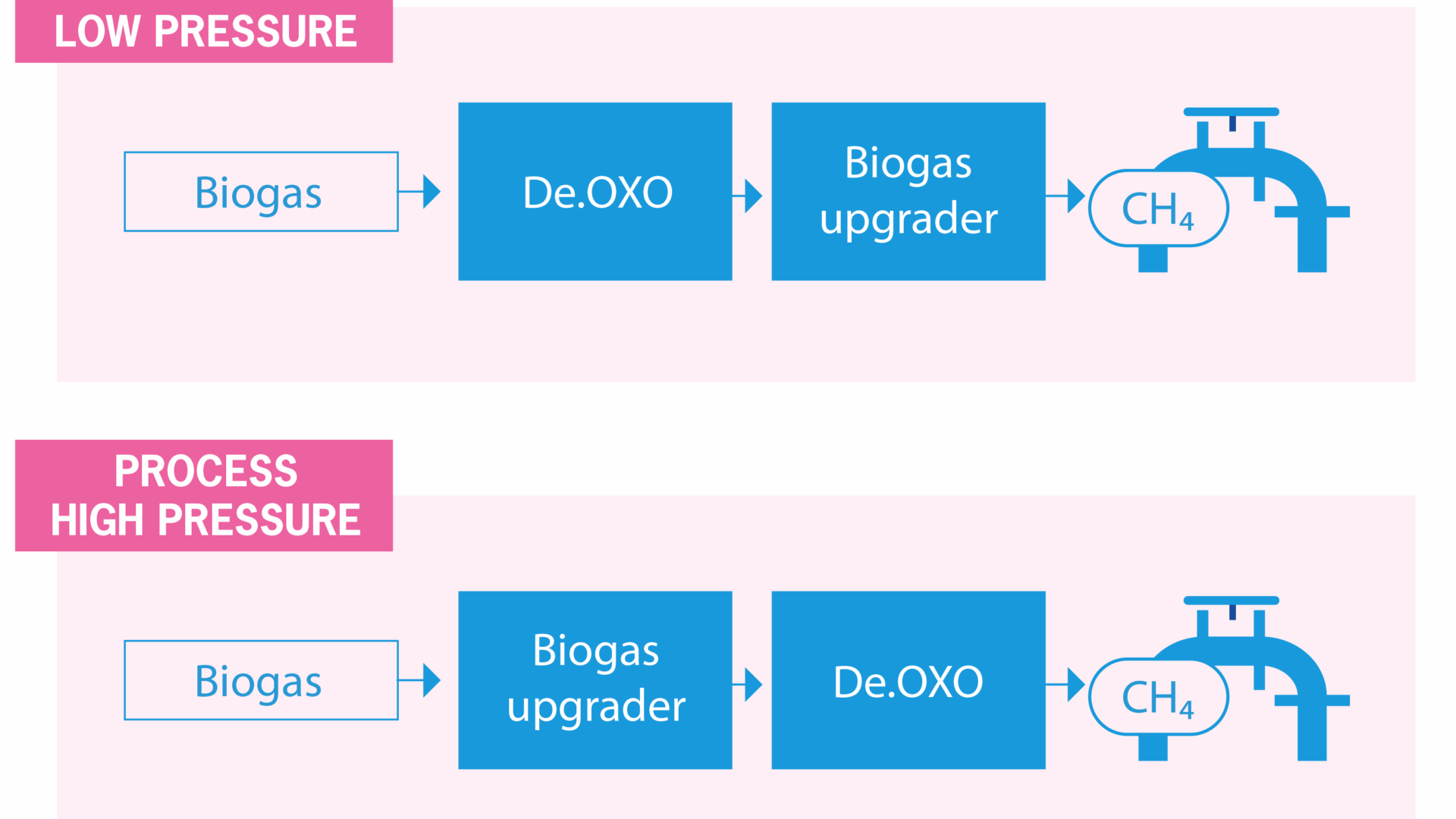

While many deoxygenation biogas technologies remove oxygen and water after the membranes at high pressure, we designed our system differently for higher efficiency. It integrates after the cooling and pretreatment step, but before compression and membrane separation. As a result, water is naturally removed in the downstream membranes, eliminating the need for an additional water removal or TSA step. This innovation reduces both CAPEX and OPEX costs.

Tailored for the biogas market

The biogas market has strict oxygen content regulations. To meet these standards, bioenergy businesses can integrate a De.OXO Biogas® system, which increases operational efficiency and the overall value of biogas. This system provides a strategic advantage for companies in the US bioenergy sector.

De.OXO Biogas® solution

Oxygen removal from biogas with in-house technology. The image below is an illustrative representation of the De.OXO Biogas®.